Maintenance

Float glass, used in most double-glazed units, is easily scratched and it is therefore recommended that hand jewellery is removed prior to cleaning.

Any proprietary household glass cleaner may be used with a soft cloth and it is recommended that heavy external grime be removed initially with a solution of soap and water.

Laminated glass or glass containing Georgian bars is cleaned in exactly the same manner.

In this type of double glazing lead strips are bonded to the inside and outside of the unit in diamond or square patterns.

Note that external lead will oxidise. This is a natural phenomenon and cannot be avoided.

Take care when cleaning leaded units as excessive pressure might dislodge the lead from the glass surface.

Scratched Glass

If scratches occur, most can be removed with jewellers’ rouge, or an equivalent rubbing compound.

NOTE: Avoid all solvent-based or abrasive cleaners.

Wash frames with a soap and water solution every four months to remove any grime and atmospheric deposits.

If required, clean with a non-abrasive proprietary cleaner, suitable for plastics, using a soft cloth.

If necessary, use a stronger, non-abrasive proprietary cleaner, such as cream, to remove any stubborn blemishes.

Take care not to disturb sealants.

Polycarbonate roofing panels fitted to these structures must be cleaned in a similar manner to PVCu frames.

Clear gutters of leaves and debris as required to avoid overflow of rainwater and ensure unobstructed drainage.

ie box gutters

Note: Avoid all solvent-based or abrasive cleaners.

Wash roof panels with a soap and water solution every four months to remove grime and atmospheric deposits.

Do not walk on conservatory roofs.

Stainless steel hardware and glazing trims

Stainless steel is guaranteed against corrosion for ten (10) years provided appropriate care and maintenance has been carried out. “Tea Staining” on stainless steel components is common and can occur on the surface of all stainless steels when contaminants are left un-cleaned. Lack of cleaning and maintenance is not covered under guarantee.

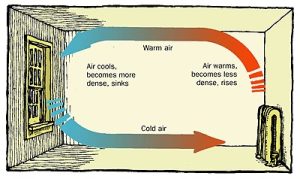

Drainage

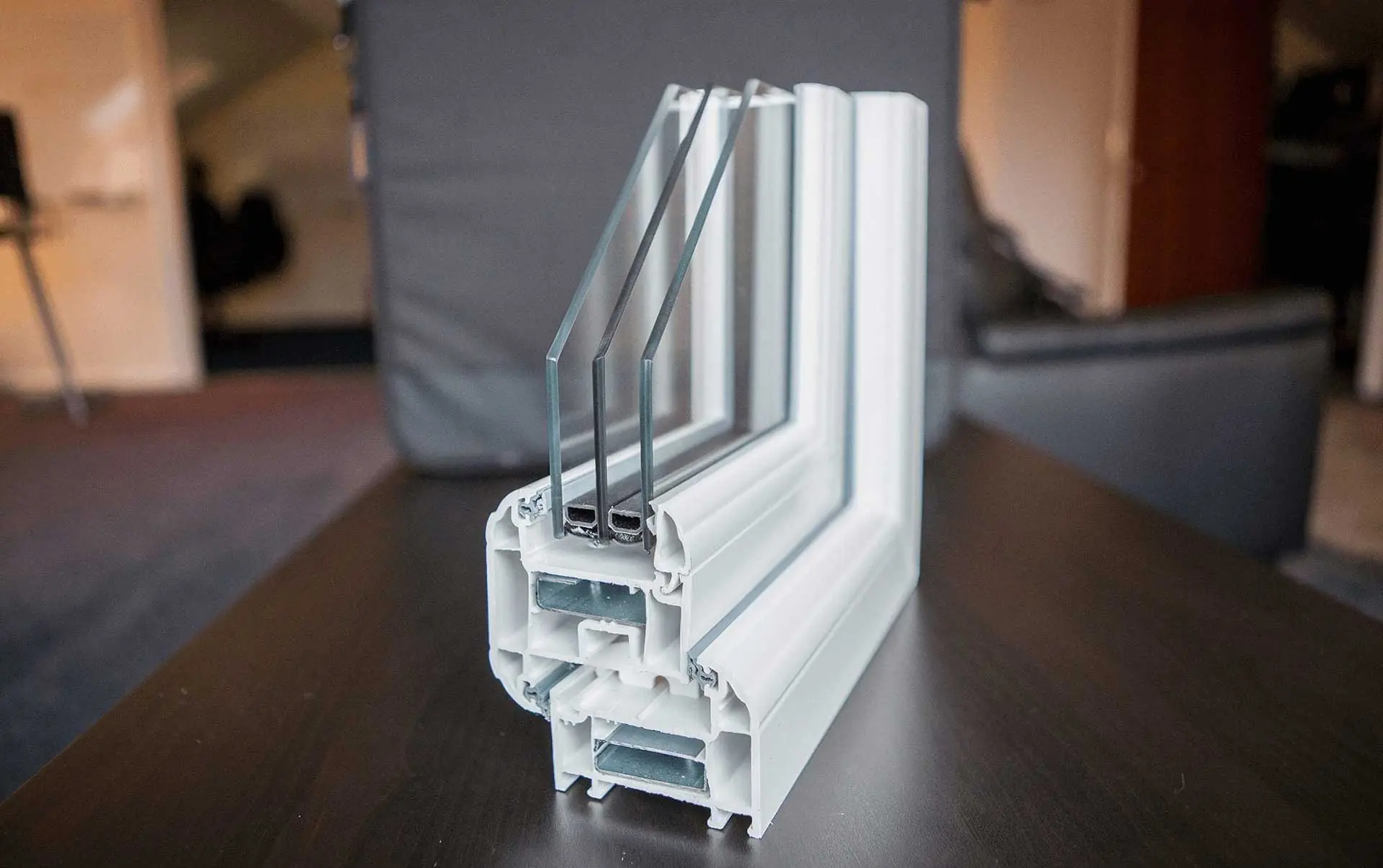

Your PVCu windows are designed with an in-built drainage system comprising of slots within the thresholds that allow any water ingress to flow to the outside. To ensure an efficient system these slots must remain unblocked.

Periodically remove dirt, clear drain holes and check drainage operation by flushing through with water.

Gaskets

During cleaning etc ensure that the gaskets fitted to your frames do not become dislodged from their grooves. Should this occur, slide back into position immediately to avoid damage when the unit is closed.

Lubrication

For lubrication of hardware etc use light machine oil lubricant (EG Silicone grease spray) every 6 months and not a freeing oil for moving parts.

Mastic Seal

Please note that some discolouration of the mastic seal is a natural occurrence and cannot be avoided.

When installed, brass/chrome is fully protected with lacquer. In time and through normal wear and tear this lacquer may peel or become tarnished.

Note that your installer cannot accept responsibility for this natural occurrence.

To refurbish your brass work, carry out the following procedure:

You are advised to protect the PVCu surfaces from chemicals etc by masking off an area around each piece of brass work.

Remove old lacquer with nail polish remover or paint stripper.

Clean and polish with suitable proprietary brass polish.

Carefully re-lacquer with a good quality product.