EXPLORE

- New SmartFrame

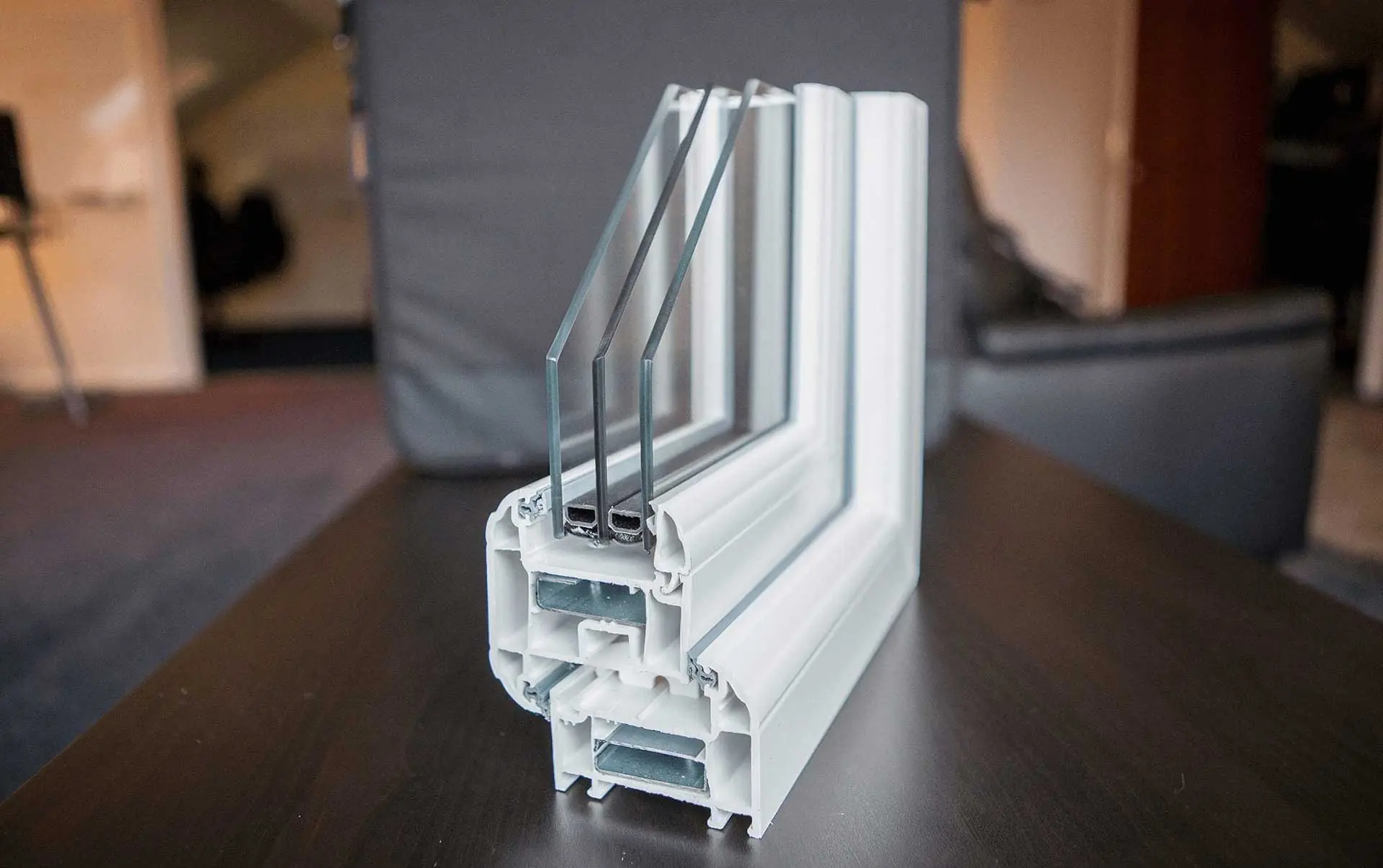

- Windows

- Doors

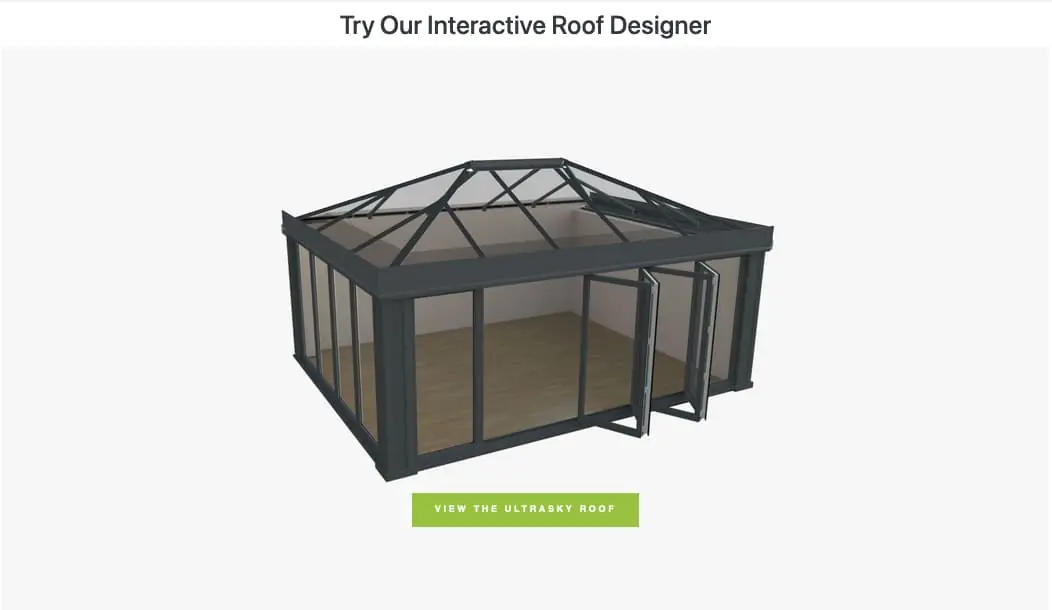

- Conservatories

- Extensions

- Roofline

- Solid Roofs

- Aftercare

- Media

- Showrooms

- Faqs

- About

- Offer

BACK

Windows

BACK

Doors

BACK

Conservatories

BACK

Showrooms

BACK

About

9.82/10

4.8/5

4.9/5